LT3581IDE-TRPBF データシートの表示(PDF) - Linear Technology

部品番号

コンポーネント説明

メーカー

LT3581IDE-TRPBF Datasheet PDF : 36 Pages

| |||

LT3581

APPLICATIONS INFORMATION

GND

1

16

SYNC

2

17

15

3

14

4

13

SHDN

CIN

–

VIN

+

5

6

A

7

8

C

C1

12

11

10

B

9

CLKOUT

GND

COUT

D1

L1

• L2

– VOUT

3581 F10

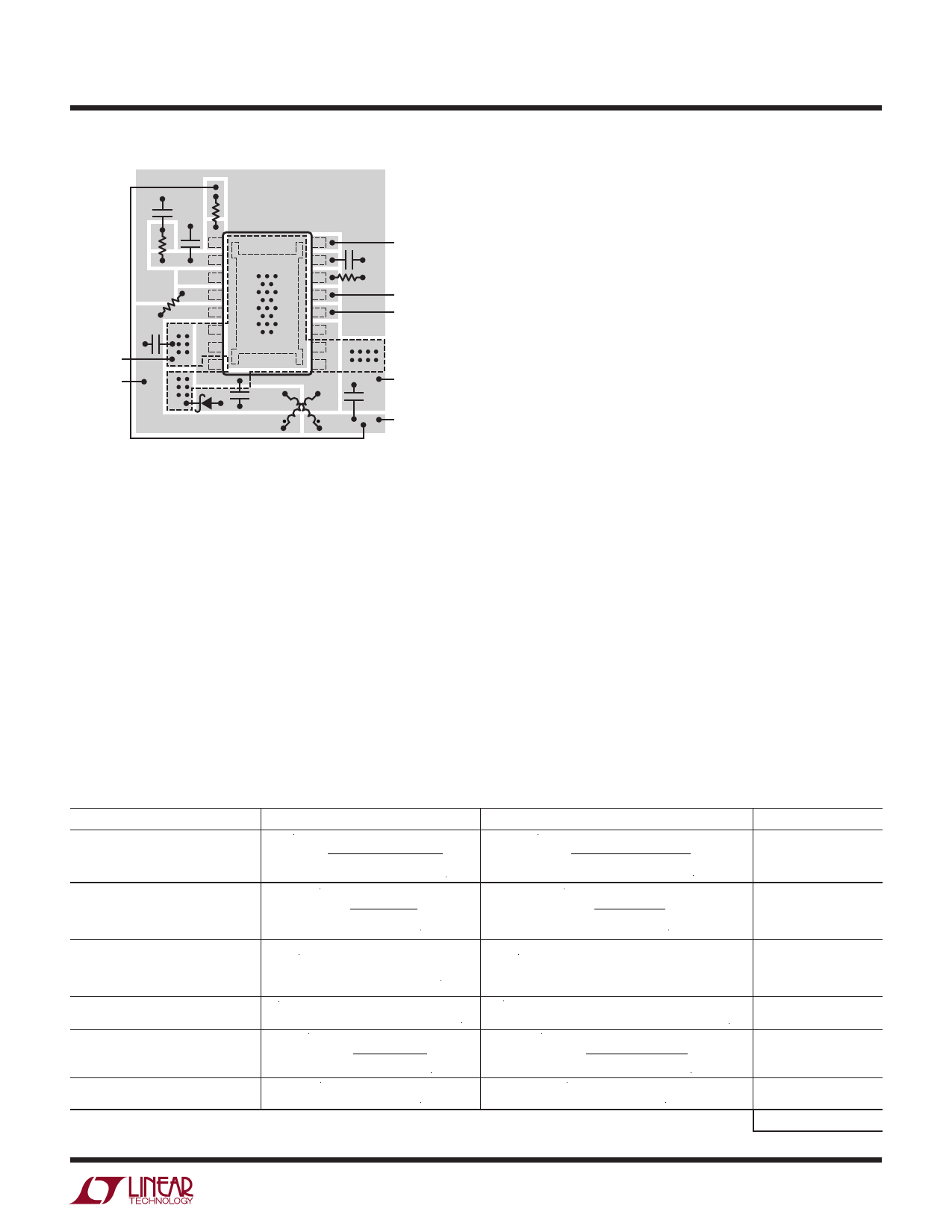

A: RETURN CIN GROUND DIRECTLY TO LT3581 EXPOSED PAD PIN 17. IT IS ADVISED

TO NOT COMBINE CIN GROUND WITH GND EXCEPT AT THE EXPOSED PAD.

B: RETURN COUT GROUND DIRECTLY TO LT3581 EXPOSED PAD PIN 17. IT IS ADVISED

TO NOT COMBINE COUT GROUND WITH GND EXCEPT AT THE EXPOSED PAD.

C: RETURN D1 GROUND DIRECTLY TO LT3581 EXPOSED PAD PIN 17. IT IS ADVISED

TO NOT COMBINE D1 GROUND WITH GND EXCEPT AT THE EXPOSED PAD.

L1, L2: MOST COUPLED INDUCTOR MANUFACTURERS USE CROSS PINOUT FOR

IMPROVED PERFORMANCE.

Figure 10. Suggested Component Placement for Dual Inductor

Inverting Topology (MSOP Shown, DFN Similar, Not to Scale.)

Pin 15 on DFN or Pin 17 on MSOP Is the Exposed Pad Which

Must Be Soldered Directly to the Local Ground Plane for

Adequate Thermal Performance. Multiple Vias to Additional

Ground Planes Will Improve Thermal Performance

THERMAL CONSIDERATIONS

Overview

For the LT3581 to deliver its full output power, it is imp

erative that a good thermal path be provided to dissipate

the heat generated within the package. This can be

accomplished by taking advantage of the thermal pad on

the underside of the IC. It is recommended that multiple

vias in the printed circuit board be used to conduct heat

away from the IC and into a copper plane with as much

area as possible.

Power and Thermal Calculations

Power dissipation in the LT3581 chip comes from four

primary sources: switch I2R losses, switch dynamic

losses, NPN base drive DC losses, and miscellaneous

input current losses. These formulas assume continuous

mode operation, so they should not be used for calculating

thermal losses or efficiency in discontinuous mode or at

light load currents.

The following example calculates the power dissipa-

tion in the LT3581 for a particular boost application

(VIN = 5V, VOUT = 12V, IOUT = 0.83A, fOSC = 2MHz, VD = 0.45V,

VCESAT = 0.21V).

To calculate die junction temperature, use the appropriate

thermal resistance number and add in worst-case ambient

temperature:

TJ = TA + θJA • PTOTAL

Table 4. Power Calculations Example for Boost Converter with VIN = 5V, VOUT = 12V, IOUT = 0.83A, fOSC = 2MHz, VD = 0.45V, VCESAT = 0.21V

DEFINITION OF VARIABLES

EQUATIONS

DESIGN EXAMPLE

VALUE

DC = SWITCH DUTY CYCLE

DC = VOUT – VIN + VD

VOUT + VD – VCESAT

DC = 12V – 5V + 0.45V

12V + 0.45V – 0.21V

DC = 60.9%

IIN = Average Switch Current

η = Power Conversion Efficiency

(typically 88% at high currents)

PSWDC = Switch I2R Loss (DC)

RSW = Switch Resistance (typically

90mΩ combined SW1 and SW2)

PSWAC = Switch Dynamic Loss (AC)

IIN

=

VOUT • IOUT

VIN • η

PSWDC = DC • IIN2 • RSW

PSWAC = 13ns • IIN • VOUT • fOSC

IIN

=

12V

5V

• 0.83A

• 0.88

PSWDC = 0.609 • (2.3A)2 • 90mΩ

PSWAC = (13ns) • 2.3A • 12V • (2MHz)

IIN = 2.3A

PSWDC = 290mW

PSWAC = 718mW

PBDC = Base Drive Loss (DC)

PBDC

=

VIN

• IIN

45

• DC

PBDC

=

5V

•2.3A •

45

0.609

PBDC = 156mW

PINP = Input Power Loss

PINP = 9mA • VIN

PINP = 9mA • 5V

PINP = 45mW

PTOTAL = 1.209W

3581fb

For more information www.linear.com/LT3581

17