935267010117 データシートの表示(PDF) - Philips Electronics

部品番号

コンポーネント説明

メーカー

935267010117 Datasheet PDF : 17 Pages

| |||

Philips Semiconductors

Frame Transfer CCD Image Sensor

Objective specification

FXA 1012

Application information

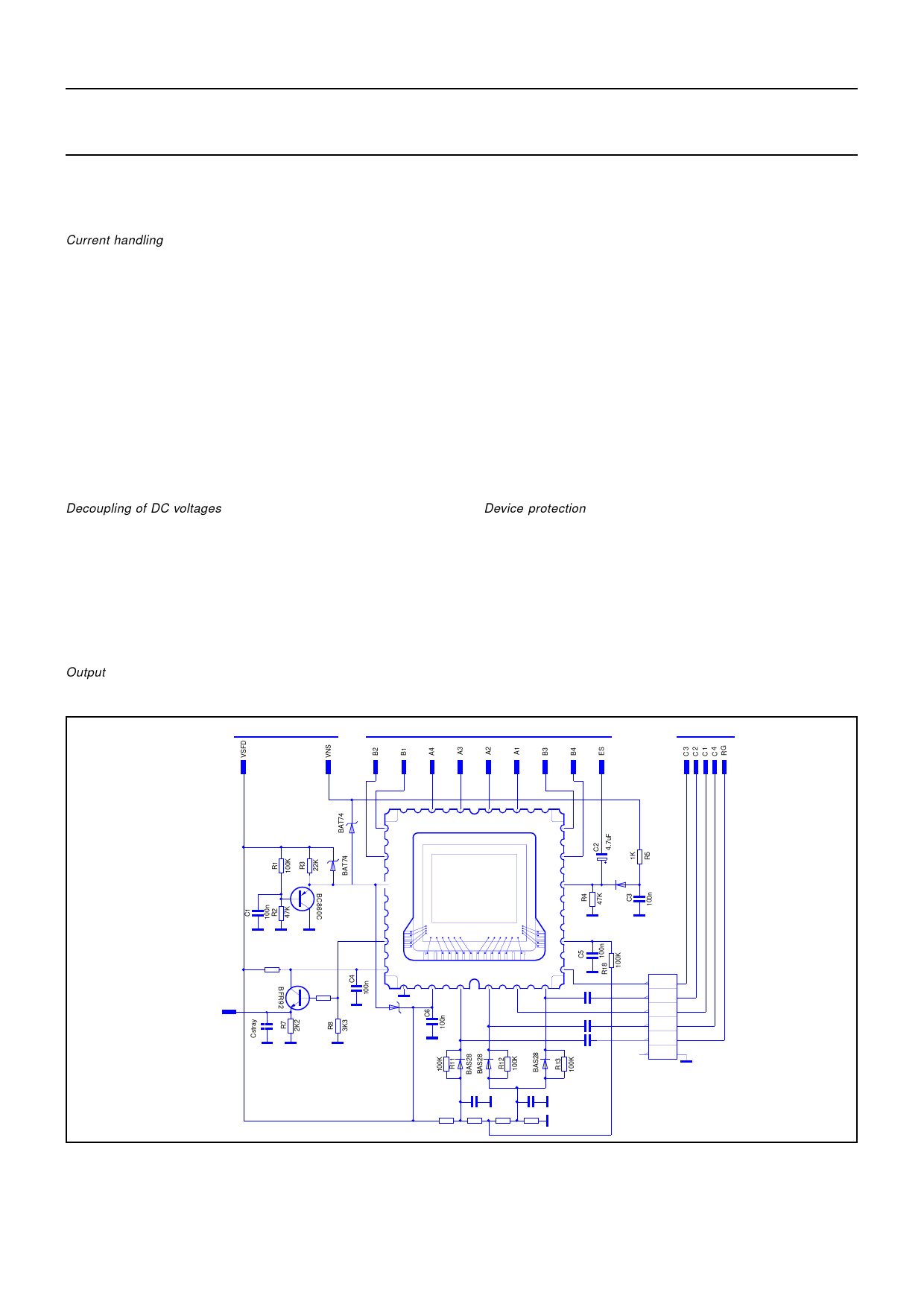

Current handling

One of the purposes of VPS is to drain the holes that are generated

during exposure of the sensor to light. Free electrons are either

transported to the VRD connection and, if excessive (from over-

exposure), free electrons are drained to VNS. No current should

flow into VPS. During overexposures a total current 0.5 to 1mA

through VPS may be expected. The PNP emitter follower in the circuit

diagram (figure 9) serves these current requirements.

VNS drains superfluous electrons as a result of overexposure. In

other words, it only sinks current. During overexposures a total current

of 0.5 to 1mA through VNS may be expected. The NPN emitter

follower in the circuit diagram meets these current requirements.

The clamp circuit, consisting of the diode and electrolytic capacitor,

enables the addition of a Charge Reset (CR) pulse on top of an

otherwise stable VNS voltage. To protect the CCD, the current

resulting from this pulse should be limited. This can be accomplished

by designing a pulse generator with a rather high output impedance.

a current source or more simply with a resistance to GND. In order

to prevent the output (which typically has an output impedance of

about 400 Ohm) from bandwidth limitation as a result of capacitive

loading, load the output with an emitter follower built from a high-

frequency transistor. Mount the base of this transistor as close as

possible to the sensor and keep the connection between the emitter

and the next stage short. The CCD output buffer can easily be

destroyed by ESD. By using this emitter follower, this danger is

suppressed; do NOT reintroduce this danger by measuring directly

on the output pin of the sensor with an oscilloscope probe. Instead,

measure on the output of the emitter follower. Slew rate limitation is

prevented by avoiding a too-small quiescent current in the emitter

follower; about 10mA should do the job. The collector of the emitter

follower should be decoupled properly to suppress the Miller effect

from the base-collector capacitance. A CCD output load resistor of

3.3 kΩ typically results in a bandwidth of 95MHz.

Decoupling of DC voltages

All DC voltages (not VNS, which has additional CR pulses as

described above) should be decoupled with a 100nF decoupling

capacitor. This capacitor must be mounted as close as possible to

the sensor pin. Further noise reduction (by bandwidth limiting) is

achieved by the resistors in the connections between the sensor

and its voltage supplies. The electrons building up the charge packets

that will reach the floating diffusion only add up to a small current,

which will flow through VRD. Therefore a large series resistor in the

VRD connection may be used.

Output

To limit the on-chip power dissipation, the output buffer is designed

with open source output. The output should therefore be loaded with

Device protection

The output buffer or VNS of the FXA 1012 is likely to be damaged if

VPS rises above SFD or RD at any time.This danger is most realistic

during power-on or power-off of the camera.

Never exceed the maximum output current. This may damage the

device permanently. The maximum output current should be limited

to 6mA. Be especially aware that the output buffers of these image

sensors are very sensitive to ESD damage.

Because of the fact that our CCDs are built on an n-substrate, we

are dealing with some parasitic NPN transistors. To avoid activation

of these transistors during switch-on and switch-off of the camera,

we recommend the application diagram of figure 9.

From CCD Supply

From V-Drivers

From PPG

CCD OUT

47E

R6

R9

100E

NC

A4

A3

A2

A1

NC

B1

B3

B2

B4

VPS

FXA 1012

VNS

NC

NC

BAS28

OUT

OG

SFD

SFS RD

RG

C4

BAT74

C3

C1

C2

C7 100n

C8 100n

C9 100n

H DRIVER

1

74ACT04

C10 100n

C11 100n

R14 R15 R16 R17

22K 100K 6K8 18K

Figure 9 - Application diagram to protect the FXA 1012

2000 January

12