ADM8690(1997) データシートの表示(PDF) - Analog Devices

部品番号

コンポーネント説明

メーカー

ADM8690 Datasheet PDF : 16 Pages

| |||

ADM8690–ADM8695

+APPLICATION INFORMATION

Increasing the Drive Current

If the continuous output current requirements at VOUT exceed

100 mA, or if a lower VCC–VOUT voltage differential is desired,

an external PNP pass transistor may be connected in parallel

with the internal transistor. The BATT ON output (ADM8691/

ADM8693/ADM8695) can directly drive the base of the exter-

nal transistor.

+5V INPUT

POWER

BATTERY

0.1µF

PNP TRANSISTOR

VCC

BATT

ON

VOUT

VBATT ADM8691

ADM8693

ADM8695

0.1µF

Figure 17. Increasing the Drive Current

Using a Rechargeable Battery for Backup

If a capacitor or a rechargeable battery is used for backup then

the charging resistor should be connected to VOUT since this

eliminates the discharge path that would exist during power-

down if the resistor is connected to VCC.

+5V INPUT

POWER

0.1µF

RECHARGEABLE

BATTERY

I = VOUT – VBATT

R

R

VCC

VOUT

VBATT

ADM869x

0.1µF

Figure 18. Rechargeable Battery

Adding Hysteresis to the Power Fail Comparator

For increased noise immunity, hysteresis may be added to the

power fail comparator. Since the comparator circuit is nonin-

verting, hysteresis can be added simply by connecting a resistor be-

tween the PFO output and the PFI input as shown in Figure 19.

When PFO is low, resistor R3 sinks current from the summing

junction at the PFI pin. When PFO is high, the series combina-

tion of R3 and R4 source current into the PFI summing junc-

tion. This results in differing trip levels for the comparator.

+7V TO +15V

INPUT

POWER

R1

+5V

7805

PFI

VCC

1.3V

PFO

R4

TO µP NMI

R2

ADM869x

R3

5V

PFO

0V

0V

VL

VH

VIN

( ) VH = 1.3V

1+ R1 + R1

R2 R3

( ) VL = 1.3V

1+ R1 – R1 (5V – 1.3V)

R2 1.3V (R3 + R4)

ASSUMING R4 < < R3 THEN

( ) HYSTERESIS VH – VL = 5V

R1

R2

Figure 19. Adding Hysteresis to the Power Fail Comparator

Monitoring the Status of the Battery

The power fail comparator can be used to monitor the status of

the backup battery instead of the power supply if desired. This

is shown in Figure 20. The PFI input samples the battery volt-

age and generates an active low PFO signal when the battery

voltage drops below a chosen threshold. It may be necessary to

apply a test load in order to determine the loaded battery volt-

age. This can be done under processor control using CEOUT.

Since CEOUT is forced high during the battery backup mode, the

test load will not be applied to the battery while it is in use, even

if the microprocessor is not powered.

+5V INPUT

POWER

BATTERY

20kΩ

OPTIONAL

TEST LOAD

VBATT

10MΩ

VCC

PFI ADM869x

10MΩ

CEOUT

PFO

LOW BATTERY

SIGNAL TO

µP I/O PIN

CEIN

FROM µP I/O PIN

APPLIES TEST LOAD

TO BATTERY

Figure 20. Monitoring the Battery Status

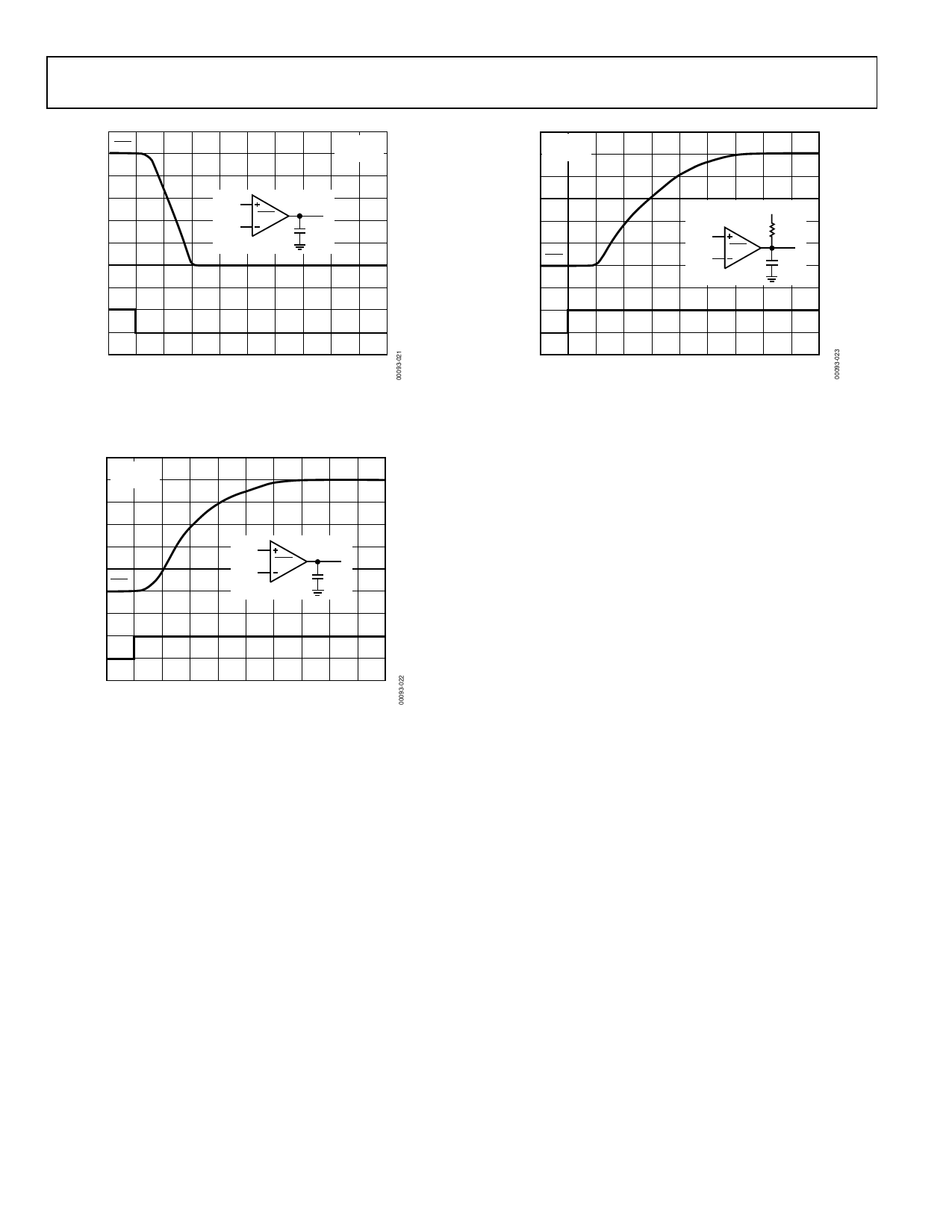

Alternate Watchdog Input Drive Circuits

The watchdog feature can be enabled and disabled under pro-

gram control by driving WDI with a three-state buffer (Figure

21a). When three-stated, the WDI input will float, thereby dis-

abling the watchdog timer.

WATCHDOG

STROBE

CONTROL

INPUT

WD I

ADM869x

Figure 21a. Programming the Watchdog Input

This circuit is not entirely foolproof, and it is possible that a

software fault could erroneously three-state the buffer. This

would then prevent the ADM869x from detecting that the mi-

croprocessor is no longer operating correctly. In most cases a

better method is to extend the watchdog period rather than dis-

abling the watchdog. This may be done under program control

using the circuit shown in Figure 21b. When the control input is

high, the OSC SEL pin is low and the watchdog timeout is set

by the external capacitor. A 0.01 µF capacitor sets a watchdog

timeout delay of 100 seconds. When the control input is low,

the OSC SEL pin is driven high, selecting the internal oscillator.

The 100 ms or the 1.6 s period is chosen, depending on which di-

ode in Figure 21b is used. With D1 inserted, the internal timeout is

set at 100 ms; with D2 inserted the timeout is set at 1.6 s.

CONTROL

INPUT*

D1

OSC SEL

D2

ADM869x

OSC IN

*LOW = INTERNAL TIMEOUT

HIGH = EXTERNAL TIMEOUT

Figure 21b. Programming the Watchdog Input

–10–

REV. 0