TD1 データシートの表示(PDF) - Unspecified

部品番号

コンポーネント説明

メーカー

TD1 Datasheet PDF : 12 Pages

| |||

An Introduction To Thermatel Technology & Products

T hermatel products utilize thermal dispersion technol-

ogy for unsurpassed accuracy and reliability in

monitoring gas flow, liquid flow, liquid level, and inter-

face. A market-proven technology, thermal dispersion has

been in use by process industries for measurement and

control purposes since the early 1960s.

Product Scope

The Thermatel product line has been structured to

provide customers with a complete range of options in

thermal dispersion technology. Each Thermatel product is

engineered and manufactured to provide the highest reli-

ability in even the most demanding process environments.

Thermatel products range from single-point switches

to the powerful TA2 Thermal Mass Flow Transmitter.

The TA2 powerful microprocessor-based electronics make

these units the premier thermal dispersion mass flow

meters in the industry. They are easy to set up, configure,

and provide high levels of accuracy, repeatability,

and diagnostics.

Applications Range

Thermatel products are in

service worldwide in many

of the most demanding

applications. As a flow

switch Thermatel is used for

gas and liquid applications

for both flow and no/low

flow detection. Typical

applications involve pump

protection, cooling air/water,

relief valve monitoring,

exhaust flows and lubrica-

tion systems. Thermatel

products provide outstand-

ing low flow sensitivity with

high rangeability.

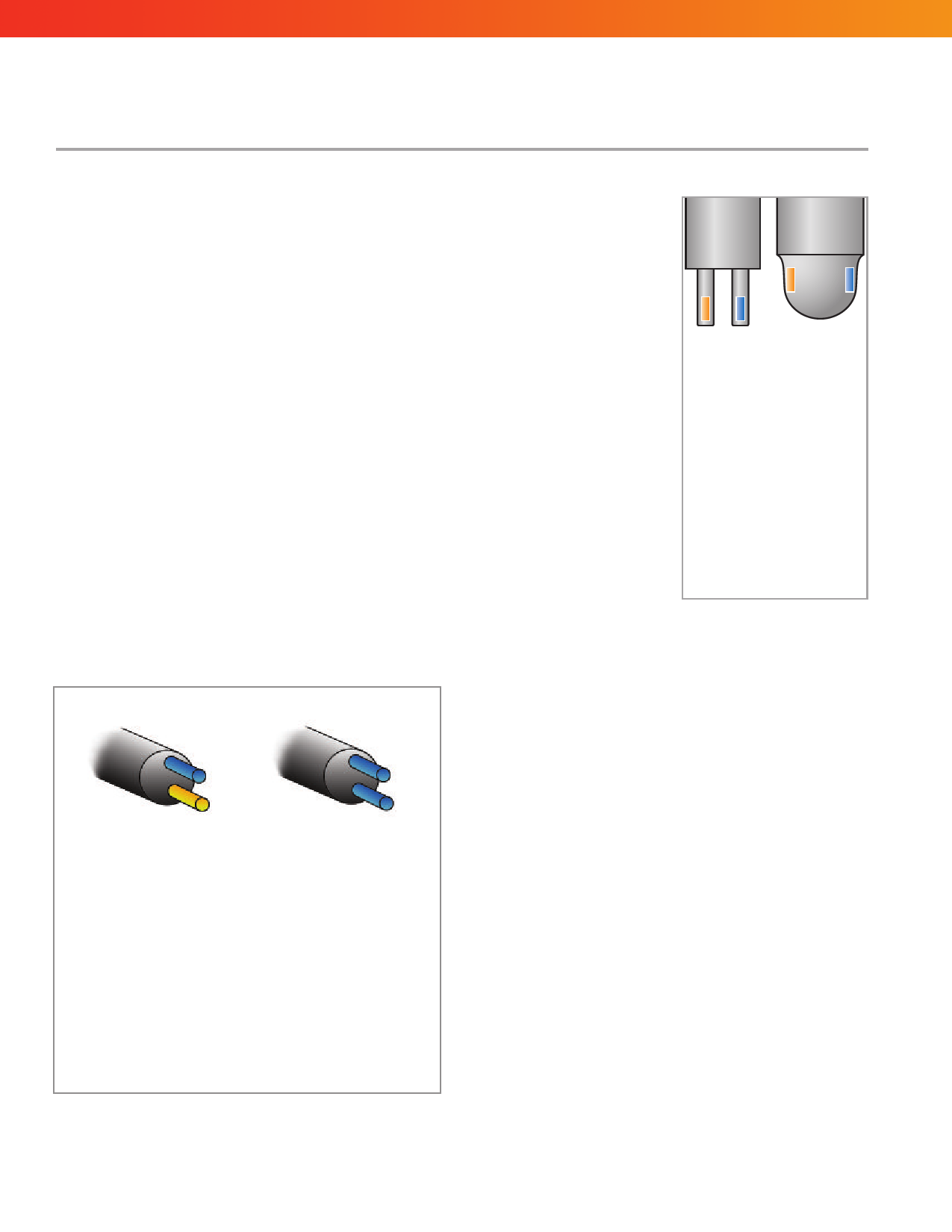

Insertion probe designs for

Thermatel switches use two

basic RTD configurations.

The twin-tip design with

exposed sensor tips is avail-

able in a broader range of

materials and sustains higher

pressures. The spherical tip

design (only available in

316L stainless steel) offers

greater sensor protection

and a faster response to

reduction flow or level.

Thermatel level switches provide outstanding perform-

ance with liquids and slurries in a wide variety of

demanding applications including interface, high viscosity,

turbulence, high temperatures, and presence of foam.

High Temperature Differential

©©©©

©

©

©©

Low Temperature Differential

Thermatel switches employ twin RTD sensors to sense

process change in level and flow applications. One sensor

measures the surrounding process temperature to provide

a reference. The second sensor is self-heated to establish

a temperature differential above the reference temperature.

In level applications, the cooling effect of contacting media

reduces the temperature difference between the RTDs. In

flow applications, an increase in flow rate further decreases

the temperature difference. In each instance, the decrease

in temperature difference triggers a relay action.

For mass flow measurement of air and gases, the

Thermatel TA2 Thermal Mass Flow Transmitter is

without peer. The easy to use instrument is installed in

numerous flow measurement applications including

combustion air flow, compressed air/gas and aeration air

flow measurement. Other common applications include

natural gas, digester/bio gas, flare lines, hydrogen, oxygen,

and many other gas flow measurement applications.

Principle of Operation: Switches

Flow and level detection is accomplished when

Thermatel’s sensing elements detect changes in the heat

transfer characteristics of the process media. As a flow

switch, Thermatel switches will rapidly detect changes in

liquid or gas flow rate by detecting heat transfer, which

increases at higher flow rates. Level detection is accom-

plished by sensing changes in the thermal conductivity of

media. Thermatel switches can also be calibrated to

sense difference in heat transfer at the interface between

two dissimilar media, such as oil/water, or water/foam.

4