RMBA19500A-58 データシートの表示(PDF) - Raytheon Company

部品番号

コンポーネント説明

メーカー

RMBA19500A-58 Datasheet PDF : 7 Pages

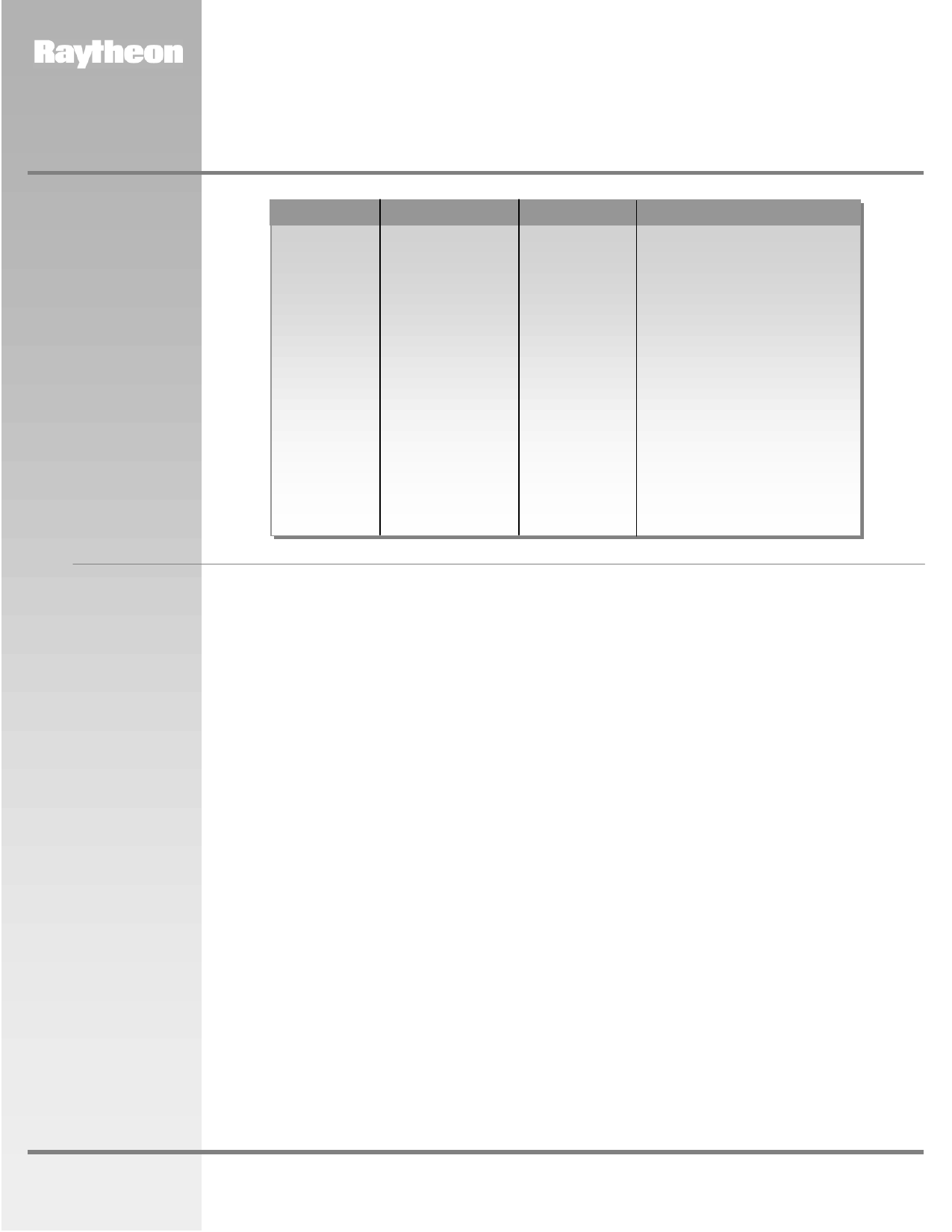

| |||

RMBA19500A-58

PCS1900 2 Watt GaAs MMIC

Power Amplifier

ADVANCED INFORMATION

Parts List

for Test Evaluation Board

(RMBA19500A-58-TB,

G654188/G654942)

Part

L1, L2

L3

C1

C2

C3, C4, C5

C10, C9

C8

C6,C7

R1-R5

R2

R3

R4

U1

HS

P1-P5

J1, J2

Board

Value

5.6 nH

8.2 nH

10 pF

2.2 pF

1500 pF

2.2 pF

10.0 uF

0.1uF

20 Ohms

180 Ohms

3.3K Ohms

30 Ohms

RMBA19500A-58

Heatsink

Terminals

SMA Connectors

FR4

EIA Size

.06” x .03”

.08” x .05”

.06” x .03”

.06” x .03”

.06” x .03”

.06” x .03”

.12”x.06”

.06”x .03”

.06”x .03”

.06”x .03”

.06”x .03”

.31” x .41

Vendor(s)

Toko (LL1608-F5N6)

Coilcraft (0805HT-8N2TKBC)

Murata (GRM39COG100J050AD)

Murata (GRM39COG2R2J050BD)

Murata (GRM39Y5V152Z50V)

Murata (GRM39COG2R2J050BD)

TDK (CC1206JX5R106M)

Murata (GRM39Y5V104Z)

IMS (RCI-0603-20R0J)

IMS (RCI-0603-1800J)

IMS (RCI-0603-3301J)

IMS (RCI-0603-30R0J)

Raytheon, G654466/G653367

Raytheon, G655548

Samtec (TSW-102-09-T-S-RE)

E.F. Johnson (142-0701-841)

Raytheon Dwg#

G654187/G654941

Thermal

Considerations

for Heat Sinking the

RMBA 19500A-58

PWB must be prepared with either an embedded copper slug in the board where the package is to be mounted or a

heat sink should be attached to the backside of PWB where the package is to be mounted on the front side. Both

the slug or the heat sink should be made of a highly conductive (electrical and thermal) material such as copper or

aluminum. The slug should be at least of the same thickness as PWB. In case of heat sink, a small pedestal should

protrude through a hole in the PWB where the package bottom is directly soldered. In either configuration, the top

surface of the slug or the pedestal should be made coplanar with the package lead mounting plane i.e., the top

surface of PWB.

Use Sn/Pb (67/37) solder (or Sn/Pn/Ag 62/36/2 solder) at 2200C for 20 seconds or less. The package bottom

should be firmly soldered to the slug or the pedestal while the pins are soldered to the respective pads on the front

side of the PWB without causing any stress on the pins. Remove flux completely if used for soldering.

www.raytheonrf.com

Characteristic performance data and specifications are subject to change without notice.

Revised November 14, 2001

Page 5

Raytheon RF Components

362 Lowell Street

Andover, MA 01810