HLMP-HB54 データシートの表示(PDF) - Avago Technologies

部品番号

コンポーネント説明

メーカー

HLMP-HB54 Datasheet PDF : 12 Pages

| |||

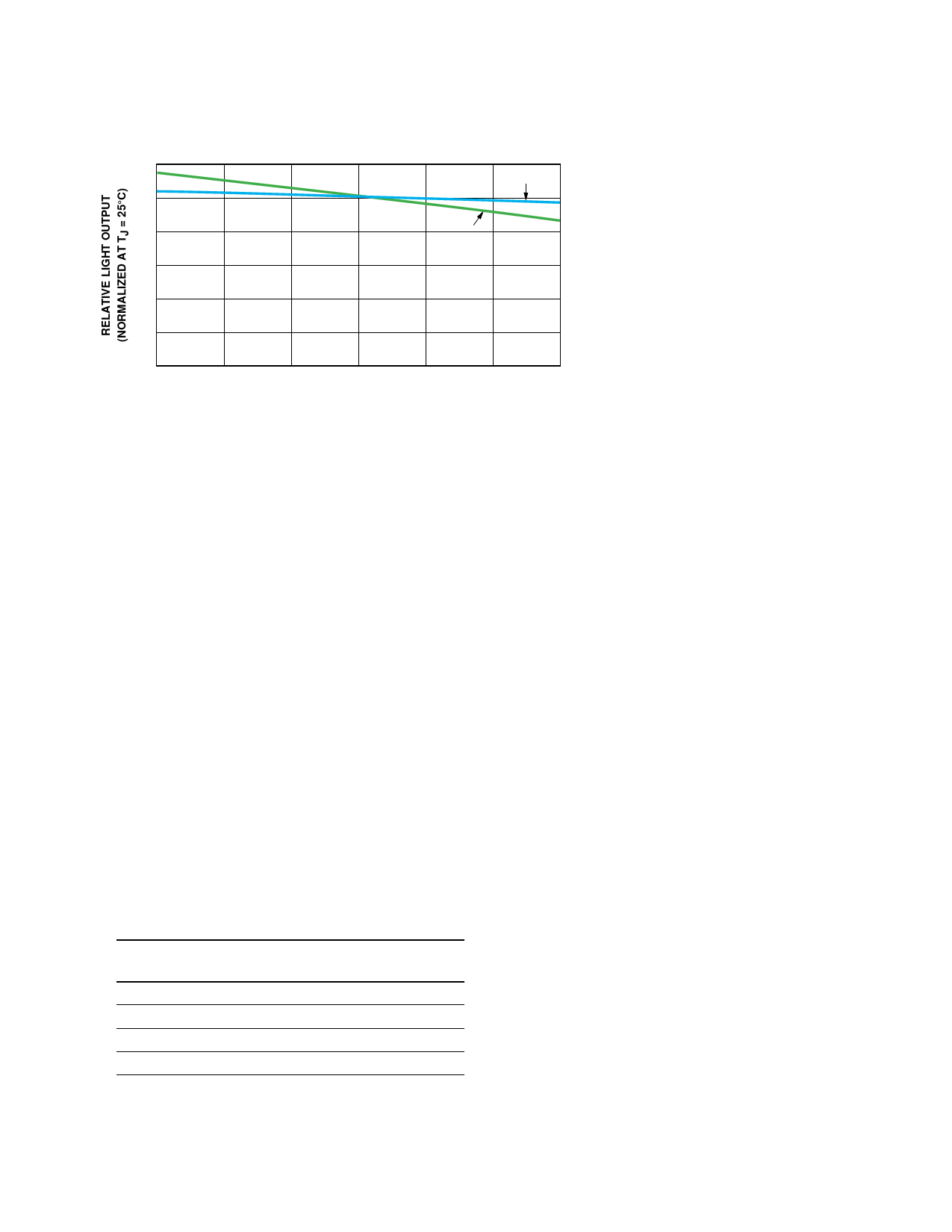

Relative Light Output vs. Junction Temperature

1.2

1.0

0.8

0.6

0.4

0.2

0

-40

BLUE

GREEN

-20

0

20

40

60

80

TJ – JUNCTION TEMPERATURE – °C

Precautions:

Lead Forming

• The leads of an LED lamp may be preformed or cut to

length prior to insertion and soldering into PC board.

• If lead forming is required before soldering, care must

be taken to avoid any excessive mechanical stress

induced to LED package. Otherwise, cut the leads of

LED to length after soldering process at room

temperature. The solder joint formed will absorb the

mechanical stress of the lead cutting from traveling to

the LED chip die attach and wirebond.

• For better control, it is recommended to use proper

tool to precisely form and cut the leads to applicable

length rather than doing it manually.

Soldering Conditions

• Care must be taken during PCB assembly and soldering

process to prevent damage to LED component.

• TheclosestLEDisallowedtosolderonboardis1.59mm

below the body (encapsulant epoxy) for those parts

without standoff.

• Recommended soldering conditions:

Pre-heat Temperature

Pre-heat Time

Peak Temperature

Dwell Time

Wave Soldering

105 °C Max.

30 sec Max.

250 °C Max.

3 sec Max.

Manual Solder

Dipping

–

–

260 °C Max.

5 sec Max.

• Wave soldering parameter must be set and maintained

according to recommended temperature and dwell

time in the solder wave. Customer is advised to

periodically check on the soldering profile to ensure the

soldering profile used is always conforming to

recommended soldering condition.

Notes:

1. PCB with different size and design (component density)

will have different heat mass (heat capacity). This might

cause a change in temperature experienced by the board if

same wave soldering setting is used. So, it is recommended

to recalibrate the soldering profile again before loading a

new type of PCB.

2. Avago Technologies' high brightness LED are using high

efficiency LED die with single wire bond as shown below.

Customer is advised to take extra precaution during wave

soldering to ensure that the maximum wave temperature

is not exceeding 250° C. Overstressing the LED during

soldering process might cause premature failure to the LED

due to delamination.

9