SIP12506DMP-TI-E3 データシートの表示(PDF) - Vishay Semiconductors

部品番号

コンポーネント説明

メーカー

SIP12506DMP-TI-E3 Datasheet PDF : 13 Pages

| |||

Product is End of Life 3/2014

SiP12506

Vishay Siliconix

WHITE LED BRIGHTNESS CONTROL

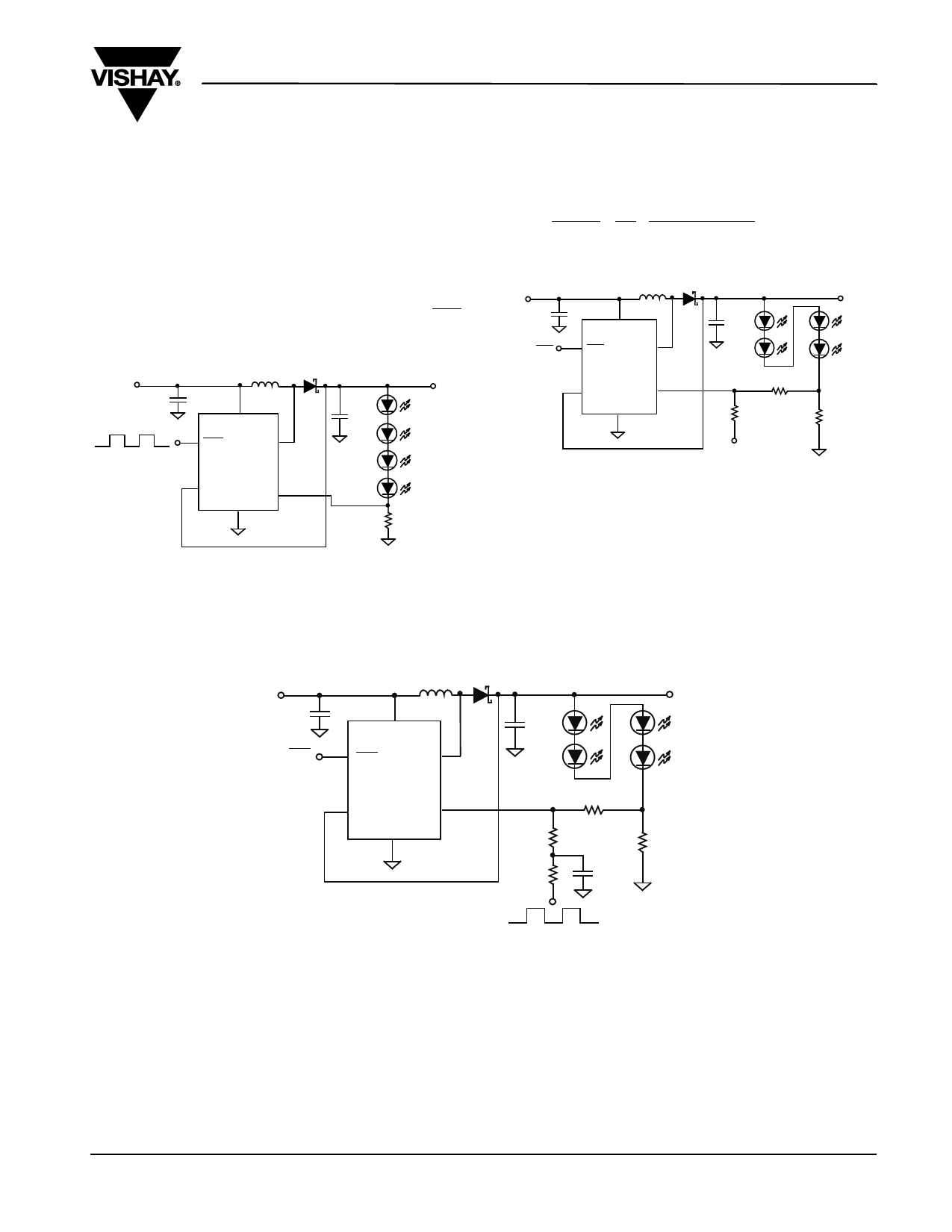

Figures 8 and 9 delineate two possible brightness control

schemes. In Figure 8, a PWM signal is injected into the shut-

down pin. The average LED current is proportional to the

duty cycle of the PWM signal and thus, the brightness will

vary from low to high as the duty cycle of the PWM signal is

increased. The frequency of the PWM signal has to be low

enough to allow the part to undergo soft-start and fully power

up at each cycle. A frequency of 100 Hz to 500 Hz is, there-

fore, recommended. The magnitude of the PWM signal

should be higher than the maximum enable voltage of SHD

pin, in order to let the dimming control perform correctly.

MBR0530

VIN

1 µF

L

2 10 µH

VIN

VO

COUT

1 µF

3 SHD

1

LX

100 - 500 Hz

SiP12506

5 VOUT

FB 4

GND

0. 208 V

6

10.5 Ω

Figure 8. SiP12506 Driving Four LEDs

In Figure 9, a more analog approach to brightness control. As

the control voltage VCTRL is increased from 0 V, the voltage

drop across R2 and R3 increases driving voltage on node A

low thereby reducing current through the White LEDs and

dimming brightness. Reducing VCTRL to about 0 V, will turn

the LEDs fully on with 20 mA of current. The equation for the

LED current can be expressed as

I LED

=

0.208 V

+

15 Ω

R2

×

R3

(0.208 V - VCTRL)

15 Ω

VIN

4.7 µF

SHD

MBR0530

2

VIN

10 µH

3 SHD

1

LX

COUT

1 µF

SiP12506

5

VOUT

GND

4

FB

0.208 V

6

R2

10 KΩ

R3

20 KΩ

VOUT

A

R1

15 Ω

VCTRL

Figure 9. White LED driver with adjustable brightness

Figure 10 demonstrates a more practical approach for dim-

ming control which is really the synthesis of the two ideas

demonstrated above. In this approach, a filtered PWM signal

acts as a DC voltage to control the brightness of the LEDs. It

is recommended that PWM signal with frequency higher than

22 kHz be used. Figures 11 and 12 illustrate other variations

of the previously mentioned ideas.

VIN

4.7 µF

SHD

MBR0530

2

VIN

10 µH

3 SHD

1

LX

COUT

1 µF

SiP12506

5 VOUT

GND

4

FB

0.208 V

6

R3

20 KΩ

R DC

100 KΩ

R2

10 KΩ

C DC

0.1 µF

VOUT

A

R1

15 Ω

PWM > 22 kHz

Figure 10. White LED driver with adjustable brightness control using a filtered PWM signal

Document Number: 73861

S-70547–Rev. D, 26-Mar-07

www.vishay.com

9