TMP37GRTZ-REEL7(2015) データシートの表示(PDF) - Analog Devices

部品番号

コンポーネント説明

メーカー

TMP37GRTZ-REEL7 Datasheet PDF : 19 Pages

| |||

Data Sheet

APPLICATIONS INFORMATION

SHUTDOWN OPERATION

All TMP35/TMP36/TMP37 devices include a shutdown

capability, which reduces the power supply drain to less than

0.5 µA maximum. This feature, available only in the SOIC_N

and the SOT-23 packages, is TTL/CMOS level-compatible,

provided that the temperature sensor supply voltage is equal in

magnitude to the logic supply voltage. Internal to the TMP35/

TMP36/TMP37 at the SHUTDOWN pin, a pull-up current

source to +VS is connected. This allows the SHUTDOWN pin to

be driven from an open-collector/drain driver. A logic low, or

zero-volt condition, on the SHUTDOWN pin is required to

turn off the output stage. During shutdown, the output of the

temperature sensors becomes high impedance where the

potential of the output pin is then determined by external

circuitry. If the shutdown feature is not used, it is recommended

that the SHUTDOWN pin be connected to +VS (Pin 8 on the

SOIC_N; Pin 2 on the SOT-23).

The shutdown response time of these temperature sensors is

shown in Figure 14, Figure 15, and Figure 16.

MOUNTING CONSIDERATIONS

If the TMP35/TMP36/TMP37 temperature sensors are thermally

attached and protected, they can be used in any temperature

measurement application where the maximum temperature

range of the medium is between −40°C and +125°C. Properly

cemented or glued to the surface of the medium, these sensors

are within 0.01°C of the surface temperature. Caution should be

exercised, especially with T-3 packages, because the leads and

any wiring to the device can act as heat pipes, introducing

errors if the surrounding air-surface interface is not isothermal.

Avoiding this condition is easily achieved by dabbing the leads

of the temper-ature sensor and the hookup wires with a bead of

thermally conductive epoxy. This ensures that the TMP35/TMP36/

TMP37 die temperature is not affected by the surrounding air

temperature. Because plastic IC packaging technology is used,

excessive mechanical stress should be avoided when fastening the

device with a clamp or a screw-on heat tab. Thermally conductive

epoxy or glue, which must be electrically nonconductive, is

recommended under typical mounting conditions.

These temperature sensors, as well as any associated circuitry,

should be kept insulated and dry to avoid leakage and corrosion.

In wet or corrosive environments, any electrically isolated metal

or ceramic well can be used to shield the temperature sensors.

Condensation at very cold temperatures can cause errors and

should be avoided by sealing the device, using electrically non-

conductive epoxy paints or dip or any one of the many printed

circuit board coatings and varnishes.

TMP35/TMP36/TMP37

THERMAL ENVIRONMENT EFFECTS

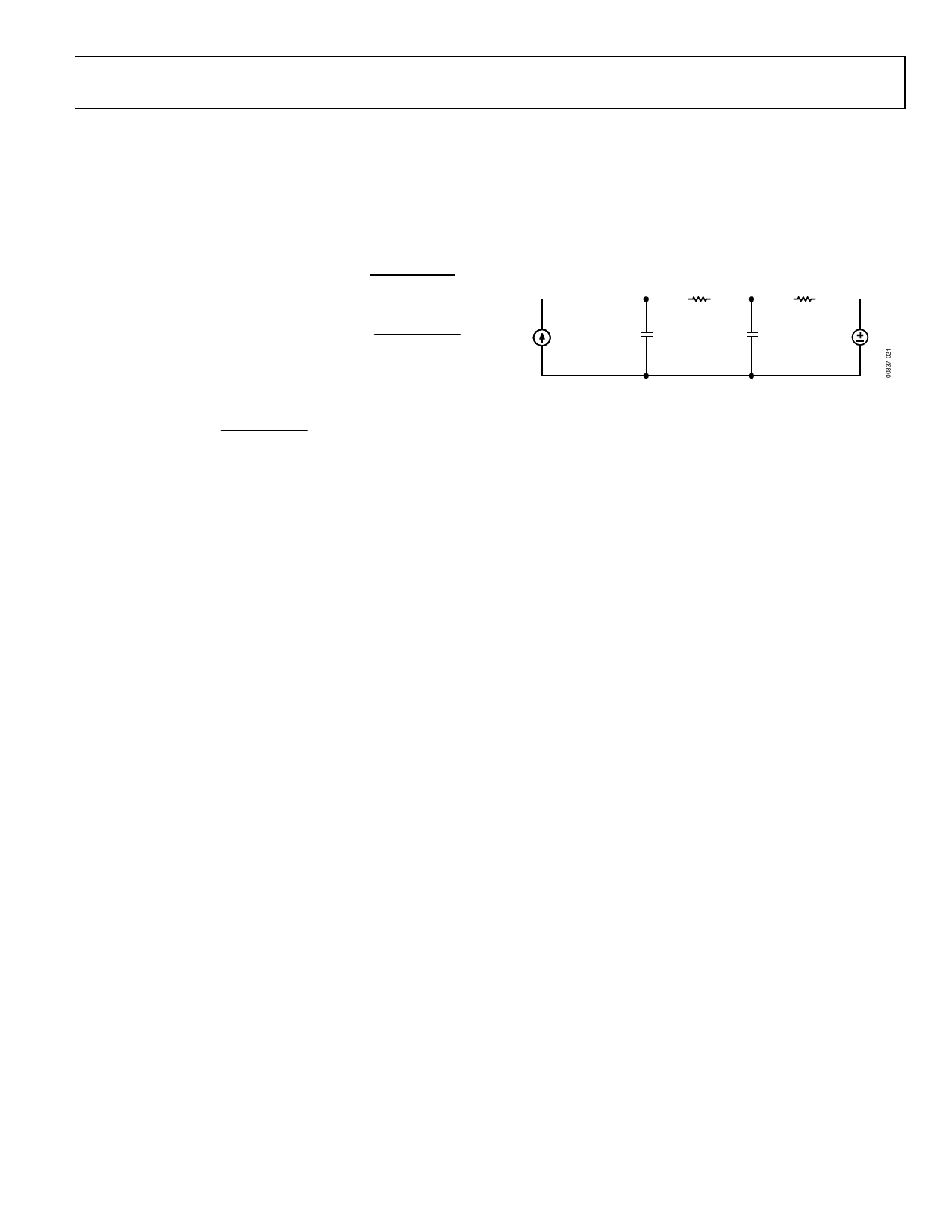

The thermal environment in which the TMP35/TMP36/TMP37

sensors are used determines two important characteristics: self-

heating effects and thermal response time. Figure 23 illustrates a

thermal model of the TMP35/TMP36/TMP37 temperature

sensors, which is useful in under-standing these characteristics.

TJ

θJC

TC

θCA

PD

CCH

CC

TA

Figure 23. Thermal Circuit Model

In the T-3 package, the thermal resistance junction-to-case, θJC,

is 120°C/W. The thermal resistance case-to-ambient, CA, is the

difference between θJA and θJC, and is determined by the char-

acteristics of the thermal connection. The power dissipation of

the temperature sensor, PD, is the product of the total voltage

across the device and its total supply current, including any

current delivered to the load. The rise in die temperature above

the ambient temperature of the medium is given by

TJ = PD × (θJC + θCA) + TA

Thus, the die temperature rise of a TMP35 SOT-23 package

mounted into a socket in still air at 25°C and driven from a 5 V

supply is less than 0.04°C.

The transient response of the TMP35/TMP36/TMP37 sensors

to a step change in the temperature is determined by the

thermal resistances and the thermal capacities of the die, CCH,

and the case, CC. The thermal capacity of CC varies with the

measurement medium because it includes anything in direct

contact with the package. In all practical cases, the thermal

capacity of CC is the limiting factor in the thermal response time

of the sensor and can be represented by a single-pole RC time

constant response. Figure 17 and Figure 19 show the thermal

response time of the TMP35/TMP36/TMP37 sensors under

various conditions. The thermal time constant of a temperature

sensor is defined as the time required for the sensor to reach

63.2% of the final value for a step change in the temperature.

For example, the thermal time constant of a TMP35 SOIC

package sensor mounted onto a 0.5" × 0.3" PCB is less than

50 sec in air, whereas in a stirred oil bath, the time constant is

less than 3 sec.

Rev. H | Page 9 of 19