MIC79050 データシートの表示(PDF) - Micrel

部品番号

コンポーネント説明

メーカー

MIC79050 Datasheet PDF : 14 Pages

| |||

MIC79050

Simple Charging

The MIC79050 is available in a three-terminal package, allow-

ing for extremely simple battery charging. When used with a

current-limited, low-power input supply, the MIC79050-4.2BS

completes a very simple, low-charge-rate, battery-charger

circuit. It provides the accuracy required for termination, while

a current-limited input supply offers the constant-current por-

tion of the algorithm.

Thermal Considerations

The MIC79050 is offered in three packages for the various

applications. The SOT-223 is most thermally efficient of

the three packages, with the power SOIC-8 and the power

MSOP-8 following suit.

Power SOIC-8 Thermal Characteristics

One of the secrets of the MIC79050’s performance is its

power SO-8 package featuring half the thermal resistance of

a standard SO-8 package. Lower thermal resistance means

more output current or higher input voltage for a given pack-

age size.

Lower thermal resistance is achieved by joining the four

ground leads with the die attach paddle to create a single-

piece electrical and thermal conductor. This concept has

been used by MOSFET manufacturers for years, proving

very reliable and cost effective for the user.

Thermal resistance consists of two main elements, θJC, or

thermal resistance junction to case and θCA, thermal resis-

tance case to ambient (Figure 8). θJC is the resistance from

the die to the leads of the package. θCA is the resistance

from the leads to the ambient air and it includes θCS, thermal

resistance case to sink, and θSA, thermal resistance sink to

ambient. Using the power SOIC-8 reduces the θJC dramati-

cally and allows the user to reduce θCA. The total thermal

resistance, θ JA, junction to ambient thermal resistance, is the

limiting factor in calculating the maximum power dissipation

capability of the device. Typically, the power SOIC-8 has a

θJC of 20°C/W, this is significantly lower than the standard

SOIC-8 which is typically 75°C/W. θCA is reduced because

pins 5-8 can now be soldered directly to a ground plane, which

significantly reduces the case to sink thermal resistance and

sink to ambient thermal resistance.

SOIC-8

qJA

qJC

qCA

ground plane

heat sink area

AMBIENT

printed circuit board

Figure 8. Thermal Resistance

Micrel, Inc.

The MIC79050 is rated to a maximum junction temperature

of 125°C. It is important not to exceed this maximum junction

temperature during operation of the device. To prevent this

maximum junction temperature from being exceeded, the

appropriate ground plane heat sink must be used.

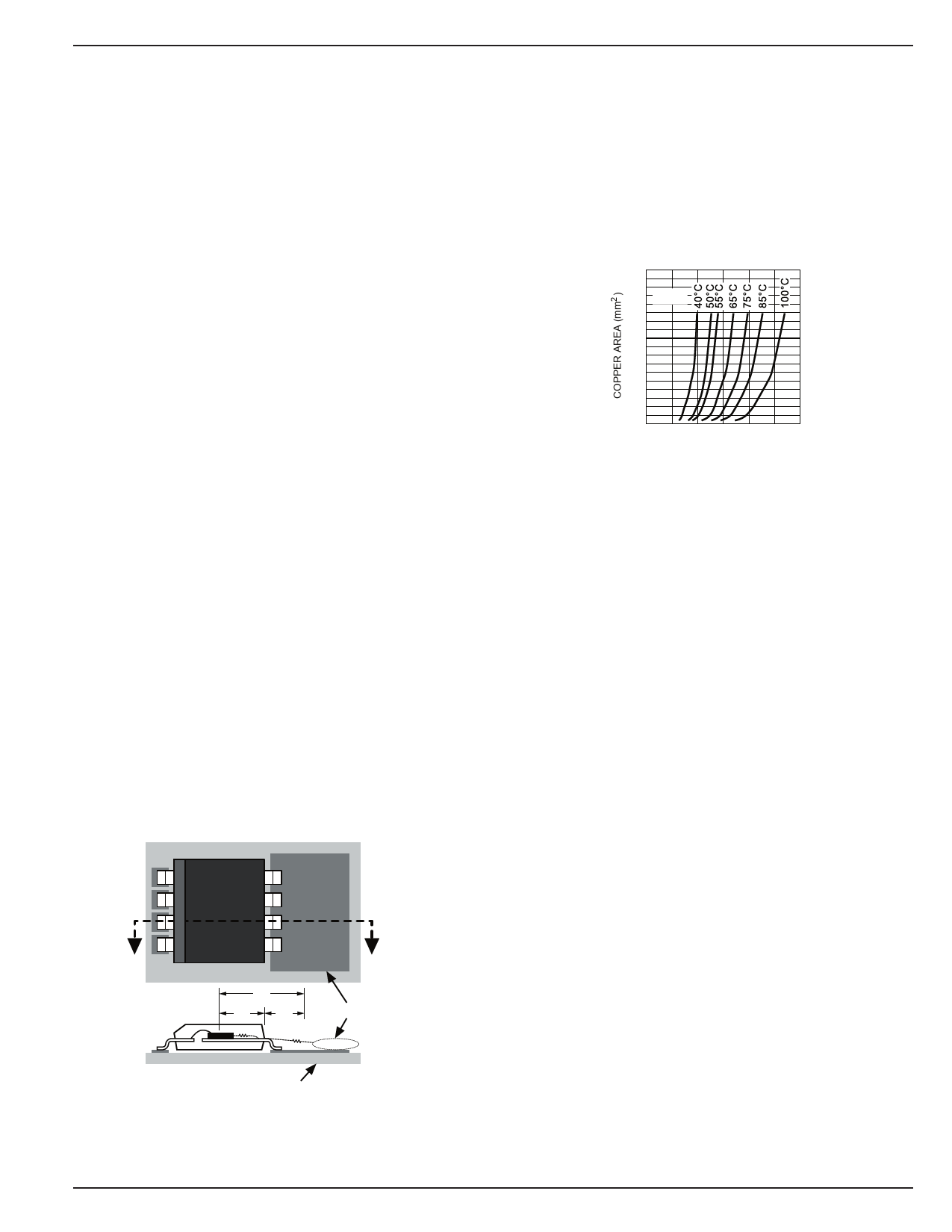

Figure 9 shows curves of copper area versus power dis-

sipation, each trace corresponding to different temperature

rises above ambient. From these curves, the minimum area

of copper necessary for the part to operate safely can be

determined. The maximum allowable temperature rise must

be calculated to determine operation along which curve.

900

800

700 ∆TJ A =

600

500

400

300

200

100

00

0.25 0.50 0.75 1.00 1.25 1.50

POWER DISSIPATION (W)

Figure 9. Copper Area vs. Power-SOIC

Power Dissipation (∆TJA)

Where ΔT = Tj(max) – Ta(max)

Tj(max) = 125°C

Ta(max) = maximum ambient operating

temperature

For example, the maximum ambient temperature is 40°C,

the ΔT is determined as follows:

ΔT = +125°C – 40°C

ΔT = +85°C

Using Figure 9, the minimum amount of required copper can

be determined based on the required power dissipation. Power

dissipation in a linear regulator is calculated as follows:

PD = (Vin-Vout)*Iout + Vin*Ignd

For example, using the charging circuit in Figure 7, assume

the input is a fixed 5V and the output is pulled down to 4.2V

at a charge current of 500mA. The power dissipation in the

MIC79050 is calculated as follows:

PD = (5V – 4.2V)*0.5A + 5V*0.012A

PD = 0.460W

From Figure 9, the minimum amount of copper required to

operate this application at a ΔT of 85C is less than 50mm2.

Quick Method

Determine the power dissipation requirements for the design

along with the maximum ambient temperature at which the

device will be operated. Refer to Figure 10 , which shows

safe operating curves for 3 different ambient temperatures:

+25°C, +50°C and +85°C. From these curves, the minimum

amount of copper can be determined by knowing the maxi-

mum power dissipation required. If the maximum ambient

August 2005

11

MIC79050