MMA02040C8200FB300 データシートの表示(PDF) - Vishay Semiconductors

部品番号

コンポーネント説明

メーカー

MMA02040C8200FB300 Datasheet PDF : 15 Pages

| |||

MMU 0102, MMA 0204, MMB 0207 - Professional

www.vishay.com

Vishay Beyschlag

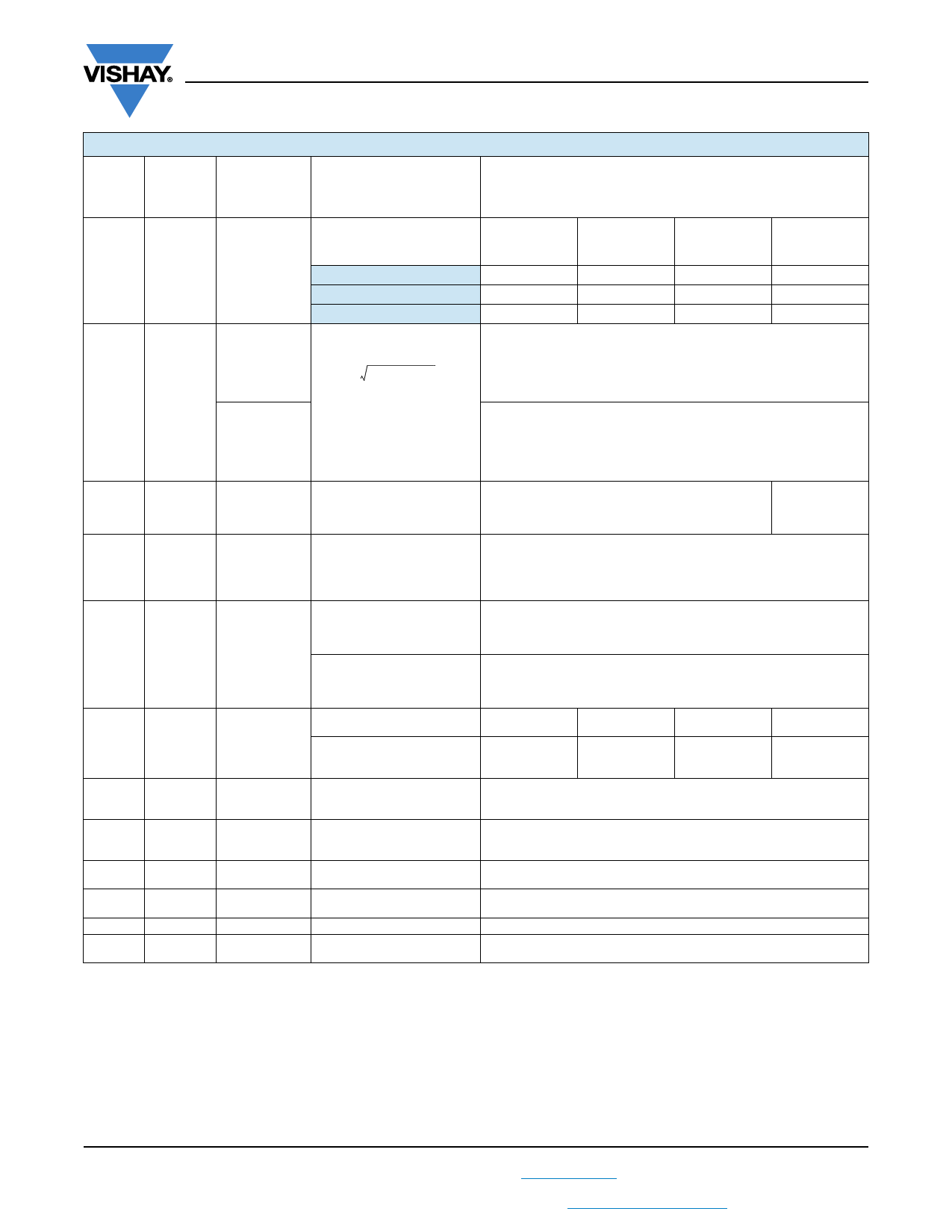

TEST PROCEDURES AND REQUIREMENTS

EN

60 115-1

CLAUSE

IEC

60 068-2 (1)

TEST

METHOD

TEST

PROCEDURE

REQUIREMENTS

PERMISSIBLE CHANGE (R)

Stability for product types:

STABILITY

CLASS 0.25

OR BETTER

STABILITY

CLASS 0.5

OR BETTER

STABILITY

CLASS 1

OR BETTER

STABILITY

CLASS 2

OR BETTER

MMU 0102 10 to 221 k 1 to < 10

<1

> 221 k

MMA 0204 10 to 332 k 1 to < 10

<1

> 332 k

MMB 0207 10 to 1 M 1 to < 10

<1

> 1 M

4.39

Periodic

electric

overload:

-

Standard

operation

mode

U = 15 x P70 x R or

U = 2 x Umax.;

whichever is the less severe;

Periodic

electric

0.1 s on; 2.5 s off;

overload:

1000 cycles

Power

operation

mode

± (0.5 % R + 5 m)

± (1 % R + 5 m)

Endurance by sweeping;

4.22

6 (Fc)

Vibration

10 Hz to 2000 Hz;

no resonance; amplitude

1.5 mm or 200 m/s2; 7.5 h

4.38

-

Electrostatic

discharge

(Human Body

Model)

IEC 61340-3-1 (1);

3 pos. + 3 neg. discharges

MMU 0102: 1.5 kV

MMA 0204: 2 kV

MMB 0207: 4 kV

±(0.05 % R + 5 m)

± (0.5 % R + 0.05 )

±(0.1 % R

+ 5 m)

Solder bath method;

SnPb40;

non-activated flux;

4.17

58 (Td) Solderability

(215 ± 3) °C; (3 ± 0.3) s

Solder bath method;

SnAg3Cu0.5 or SnAg3.5;

non-activated flux;

(235 ± 3) °C; (2 ± 0.2) s

Good tinning ( 95 % covered); no visible damage

Good tinning ( 95 % covered); no visible damage

Solder bath method;

±(0.05 % R

±(0.1 % R

±(0.25 % R ±(0.25 % R

Resistance

(260 ± 5) °C; (10 ± 1) s

+ 10 m)

+ 10 m)

+ 10 m)

+ 10 m)

4.18

58 (Td)

to soldering

heat

Reflow method 2

(IR/forced gas convection);

(260 ± 5) °C; (10 ± 1) s

±(0.02 % R

+ 10 m)

±(0.05 % R

+ 10 m)

±(0.05 % R

+ 10 m)

±(0.1 % R

+ 10 m)

Component

4.29

45 (XA)

solvent

resistance

Isopropyl alcohol;

50 °C; method 2

No visible damage

4.30

45 (XA)

Solvent

resistance

of marking

Isopropyl alcohol;

50 °C; method 1, toothbrush

Marking legible; no visible damage

4.32

21 (Ue3)

Shear

(adhesion)

45 N

No visible damage

4.33

21 (Ue1)

Substrate

bending

Depth 2 mm,

3 times

No visible damage, no open circuit in bent position

± (0.05 % R + 5 m) (2)

4.7

4.35

-

Voltage proof

URMS = Uins; 60 s

-

Flammability

IEC 60695-11-5 (1),

needle flame test; 10 s

No flashover or breakdown

No burning after 30 s

Notes

(1) The quoted IEC standards are also released as EN standards with the same number and identical contents

(2) Special requirements apply to MICRO-MELF, MMU 0102:

• R < 100 ± (0.25 % R + 10 m)

• 100 R 221 k ± 0.1 % R

• 221 k < R: ± 0.25 % R

Revision: 06-Apr-18

11

Document Number: 28713

For technical questions, contact: melf@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000