HT46C24 データシートの表示(PDF) - Holtek Semiconductor

部品番号

コンポーネント説明

メーカー

HT46C24 Datasheet PDF : 51 Pages

| |||

HT46R24/HT46C24

Interrupt Source

External Interrupt

Timer/Event Counter 0 Overflow

Timer/Event Counter 1 Overflow

A/D Converter Interrupt

I2C Bus Interrupt

Priority

1

2

3

4

5

Vector

04H

08H

0CH

10H

14H

The Timer/Event Counter 0/1 interrupt request flag (T0F,

T1F), external interrupt request flag (EIF), A/D converter

request flag (ADF), the I2C Bus interrupt request flag

(HIF), enable timer/event counter bit (ET0I, ET1I), en-

able external interrupt bit (EEI), enable A/D converter in-

terrupt bit (EADI), enable I2C Bus interrupt bit (EHI) and

enable master interrupt bit (EMI) constitute an interrupt

control register 0 (INTC0) and an interrupt control regis-

ter 1 (INTC1) which are located at 0BH and 1EH in the

data memory. EMI, EEI, ET0I, ET1I, EADI, EHI are used

to control the enabling/disabling of interrupts. These bits

prevent the requested interrupt from being serviced.

Once the interrupt request flags (T0F, T1F, EIF, ADF,

HIF) are set, they will remain in the INTC0 and INTC1

register until the interrupts are serviced or cleared by a

software instruction.

It is recommended that a program does not use the

²CALL subroutine² within the interrupt subroutine. Inter-

rupts often occur in an unpredictable manner or need to

be serviced immediately in some applications. If only one

stack is left and enabling the interrupt is not well con-

trolled, the original control sequence will be damaged

once the ²CALL² operates in the interrupt subroutine.

Oscillator Configuration

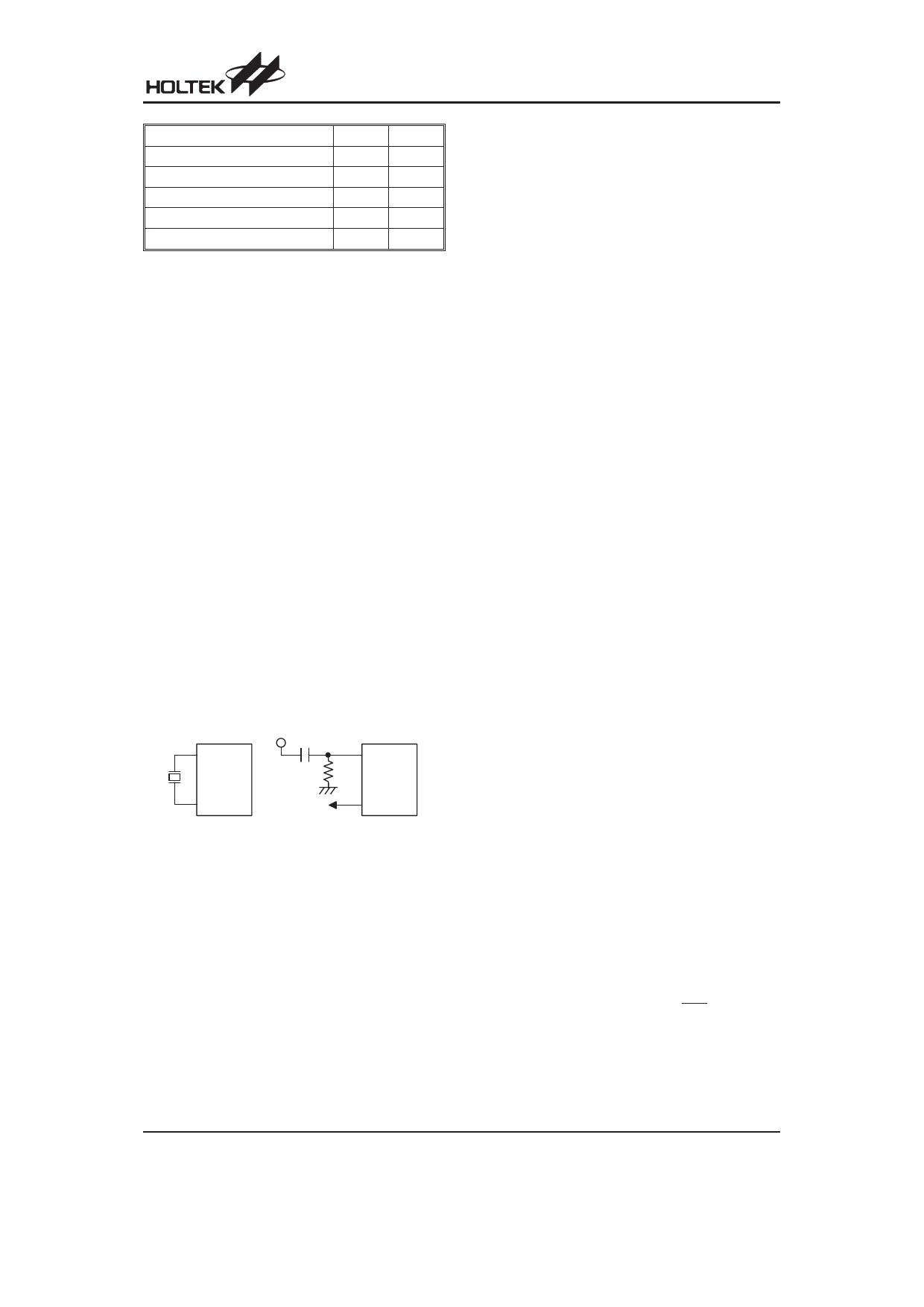

There are two oscillator circuits in the microcontroller.

O SC1

V DD

470pF

O SC1

O SC2

fS Y S /4

O SC2

C r y s ta l O s c illa to r

R C O s c illa to r

System Oscillator

Both are designed for system clocks, namely the RC os-

cillator and the Crystal oscillator, which are determined

by the option. No matter what oscillator type is selected,

the signal provides the system clock. The HALT mode

stops the system oscillator and ignores an external sig-

nal to conserve power.

If an RC oscillator is used, an external resistor between

OSC1 and VSS is required and the resistance must

range from 30kW to 750kW. The system clock, divided

by 4, is available on OSC2 with pull-high resistor, which

can be used to synchronize external logic. The RC os-

cillator provides the most cost effective solution. How-

ever, the frequency of oscillation may vary with VDD,

temperatures and the chip itself due to process varia-

tions. It is, therefore, not suitable for timing sensitive

operations where an accurate oscillator frequency is

desired.

If the Crystal oscillator is used, a crystal across OSC1

and OSC2 is needed to provide the feedback and phase

shift required for the oscillator, and no other external

components are required. Instead of a crystal, a resona-

tor can also be connected between OSC1 and OSC2 to

get a frequency reference, but two external capacitors in

OSC1 and OSC2 are required (If the oscillating fre-

quency is less than 1MHz).

The WDT oscillator is a free running on-chip RC oscillator,

and no external components are required. Even if the sys-

tem enters the power down mode, the system clock is

stopped, but the WDT oscillator still works with a period of

approximately 65ms at 5V. The WDT oscillator can be dis-

abled by option to conserve power.

Watchdog Timer - WDT

The WDT clock source is implemented by a dedicated

RC oscillator (WDT oscillator) or instruction clock (sys-

tem clock divided by 4) decided by options. This timer is

designed to prevent a software malfunction or sequence

jumping to an unknown location with unpredictable re-

sults. The watchdog timer can be disabled by a option. If

the watchdog timer is disabled, all the executions re-

lated to the WDT result in no operation.

Once an internal WDT oscillator (RC oscillator with pe-

riod 65ms at 5V normally) is selected, it is divided by

212~215 (by option to get the WDT time-out period). The

WDT time-out minimum period is 300ms~600ms. This

time-out period may vary with temperature, VDD and

process variations. By selection from the WDT option,

longer time-out periods can be realized. If the WDT

time-out is selected 215, the maximum time-out period is

divided by 215~216about 2.1s~4.3s.

If the WDT oscillator is disabled, the WDT clock may still

come from the instruction clock and operate in the same

manner except that in the HALT state the WDT may stop

counting and lose its protecting purpose. In this situation

the logic can only be restarted by external logic. If the

device operates in a noisy environment, using the

on-chip RC oscillator (WDT OSC) is strongly recom-

mended, since the HALT will stop the system clock.

The WDT overflow under normal operation will initialize

²chip reset² and set the status bit TO. Whereas in the

HALT mode, the overflow will initialize a ²warm reset²

only the program counter and stack pointer are reset to

zero. To clear the contents of WDT, three methods are

adopted; external reset (a low level to RES), software in-

structions, or a HALT instruction. The software instruc-

tions include CLR WDT and the other set CLR WDT1

and CLR WDT2. Of these two types of instruction, only

one can be active depending on the option - ²CLR WDT

times selection option². If the ²CLR WDT² is selected (i.e.

Rev. 2.00

11

March 2, 2006